Release liners are an essential component in a variety of industries, including labeling, hygiene, construction, automotive, and more. They are used to protect adhesive surfaces during storage and transport and can be made from a variety of materials, including paper, film, and foil. Choosing the right release liner for your application is critical to ensuring the success of your product and can be a complex process. In this blog, we will explore the factors that you should consider when selecting a release liner for your application and how Adiambe Papers Private Limited has played a part in this process.

The first step in choosing the right release liner is to consider the type of adhesive that you are using. Some adhesives require a higher release force, while others require a lower release force. The release force is the amount of force required to remove the release liner from the adhesive surface. If the release force is too high, the adhesive may not stick to the substrate properly, while if it is too low, the liner may not release properly, resulting in web breaks or adhesive transfer.

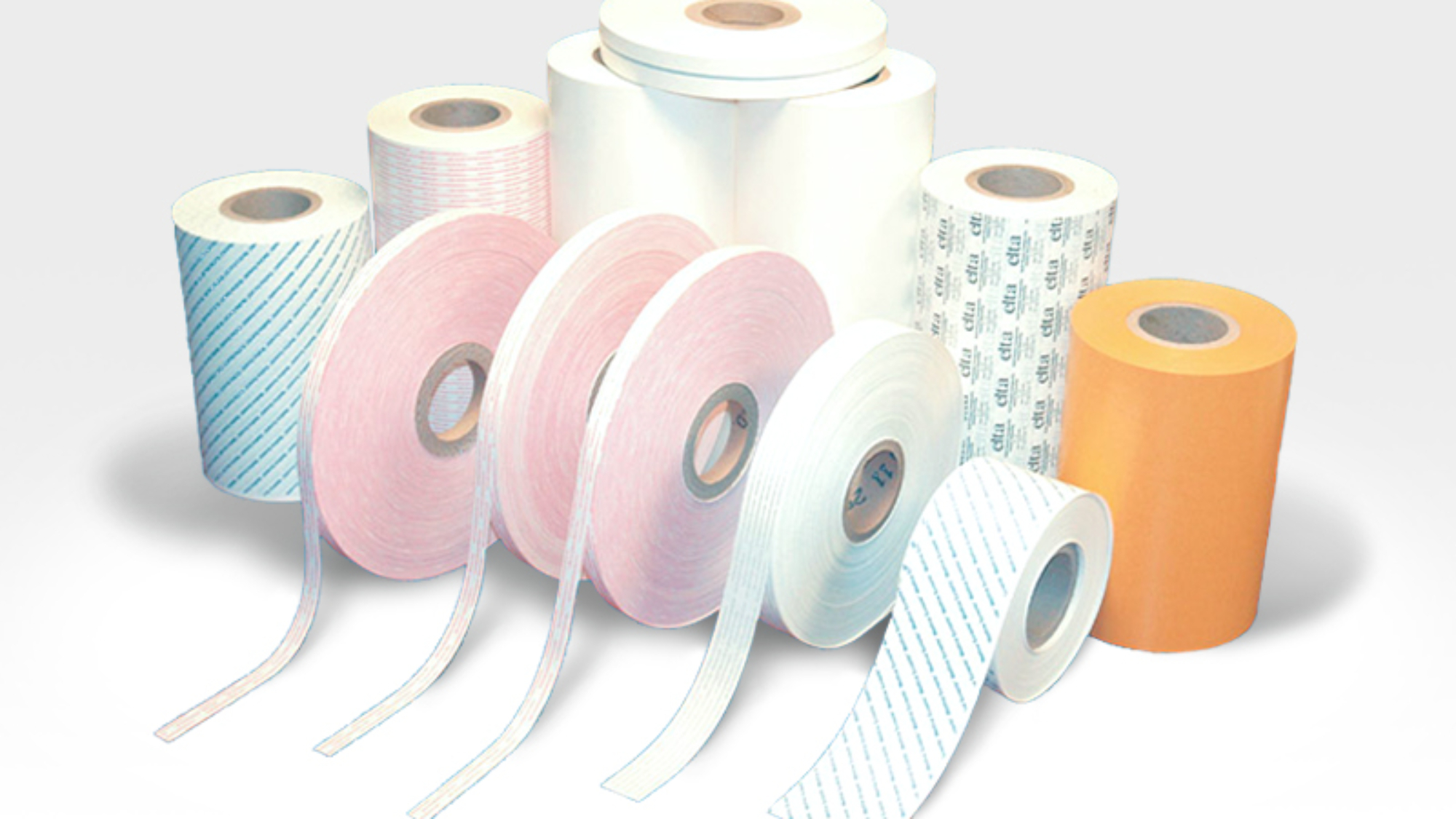

The second factor to consider is the substrate material. Release liners are available in a variety of materials, including paper, film, and foil. Each material has different properties and is suited for different applications. For example, paper liners are ideal for label stock applications, while film liners are better suited for more demanding applications, such as in the hygiene or automotive industries.

The third factor to consider is the release coating. Release coatings are used to reduce the release force between the liner and the adhesive. They can be either solvent-based or solventless. Solvent-based coatings are typically less expensive but may have VOC emissions and environmental concerns. Solventless coatings are more environmentally friendly, but may have higher costs. Adiambe Papers Private Limited offers solventless release liners that are ideal for a variety of applications.

The fourth factor to consider is the release liner’s physical properties. These include the liner’s thickness, stiffness, and strength. The liner’s thickness should be matched to the application’s requirements to ensure proper release and adhesion. The liner’s stiffness should also be matched to the application to prevent web breaks during the manufacturing process. Finally, the liner’s strength should be sufficient to withstand the stresses of transport and storage.

Adiambe Papers Private Limited is a leading manufacturer of specialty release liners in India. The company offers a wide range of release liners, including solventless release liners in a variety of paper substrates and various types of films. The company’s coating width of 2.1 meters is the widest in India, allowing them to offer their customers the best quality and flexibility in manufacturing release liners.

Adiambe Papers Private Limited’s commitment to quality and customer satisfaction has made them a leader in the release liner industry. The company uses state-of-the-art manufacturing processes and equipment to ensure that their release liners meet the highest standards of quality and performance. Their team of experts is always available to help customers choose the right release liner for their application and provide technical support throughout the manufacturing process.

In conclusion, choosing the right release liner for your application is critical to the success of your product. Factors to consider when selecting a release liner include the type of adhesive, substrate material, release coating, and physical properties. Adiambe Papers Private Limited is a leader in the release liner industry and offers a wide range of release liners, including solventless release liners in a variety of paper substrates and various types of films. The company’s commitment to quality and customer satisfaction makes them an ideal partner for any release liner needs.

Add a Comment