The hygiene industry is a vital component of modern society, with a wide range of products designed to promote cleanliness and maintain health and safety. Release liners are an essential component in this industry, providing a crucial layer of protection for hygiene products such as diapers, sanitary napkins, and medical dressings.

Release liners serve as the backing for self-adhesive products, providing protection and ensuring that the adhesive remains in place until the product is ready to be used. In the hygiene industry, release liners play a crucial role in maintaining product integrity and ensuring that the adhesive stays in place, even during rigorous activity.

The role of release liners in the hygiene industry is particularly important for disposable products such as diapers, sanitary napkins, and medical dressings. These products must be manufactured to the highest standards of quality and safety, and release liners help ensure that the adhesive remains in place and the product remains effective, even during use.

For example, in the case of diapers, the release liner must provide a barrier between the adhesive and the skin, protecting against skin irritation and ensuring that the adhesive remains in place. Similarly, in the case of sanitary napkins, the release liner must be able to withstand the rigors of physical activity and ensure that the adhesive remains in place, providing maximum protection and comfort.

Adiambe Papers Private Limited has been operating in the release liner industry since 2013, and they have played a significant role in advancing the technology used in release liners for the hygiene industry. The company is located in Kolkata and specializes in the manufacture of solventless release liners for a variety of applications.

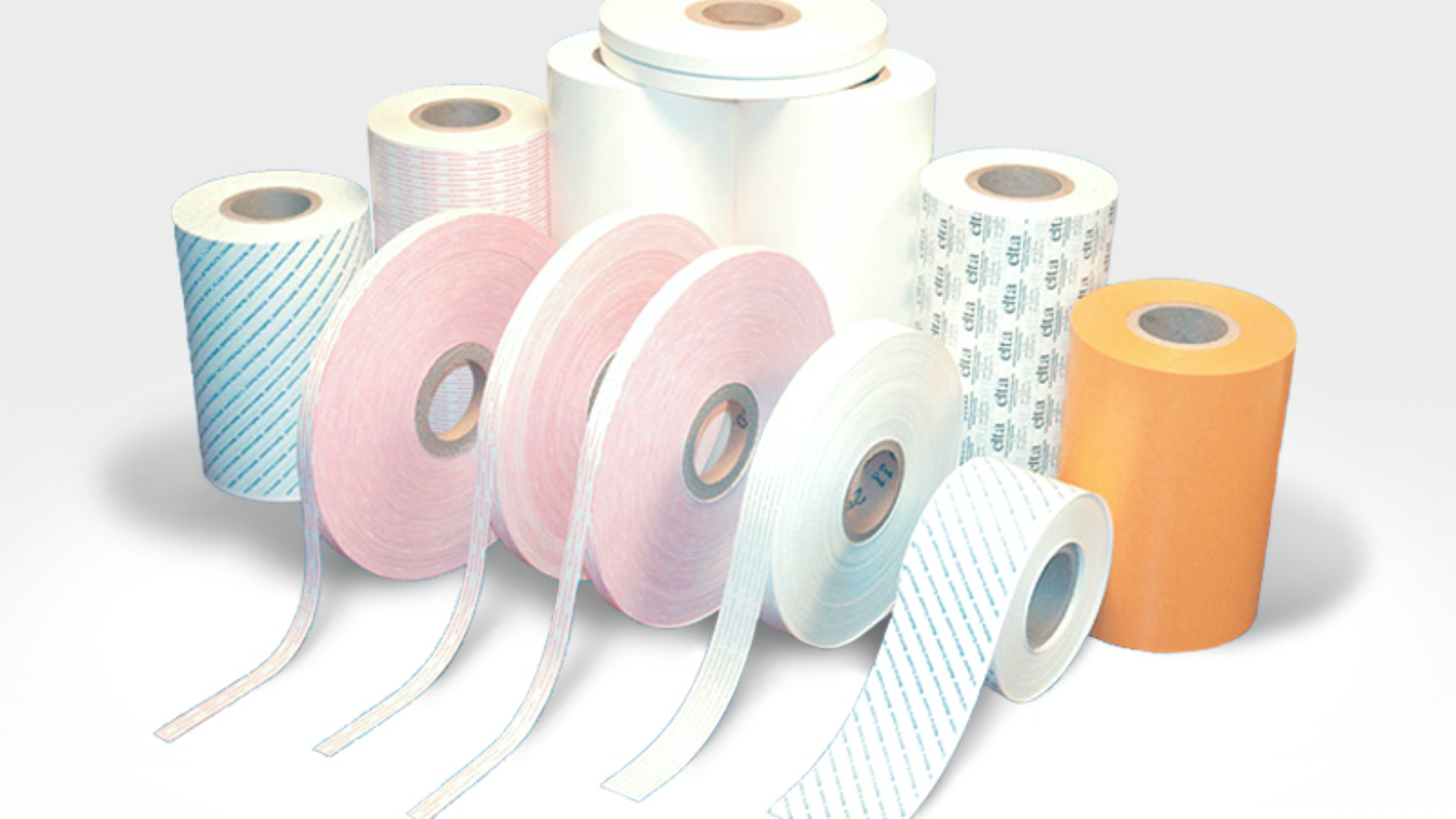

Adiambe Papers’ product range consists of release liners for label stock, hygiene, industrial, automotive, and construction, among others. They also provide release liners for self-adhesive envelopes and graphic applications. With a coating width of 2.1 meters, the company is able to produce the widest release liners in India, enabling them to manufacture products of the highest quality.

Adiambe Papers is committed to providing innovative solutions for the hygiene industry, and they are continuously exploring new technologies and approaches to improve the performance of their release liners. They are also dedicated to reducing waste and minimizing their environmental impact, utilizing eco-friendly approaches in their production processes.

In conclusion, release liners play a crucial role in the hygiene industry, providing a vital layer of protection and ensuring that hygiene products remain effective and safe during use. Adiambe Papers Private Limited is at the forefront of this industry, providing innovative and eco-friendly solutions for a wide range of applications. With their commitment to quality and innovation, Adiambe Papers is poised to continue their contributions to the hygiene industry for years to come.